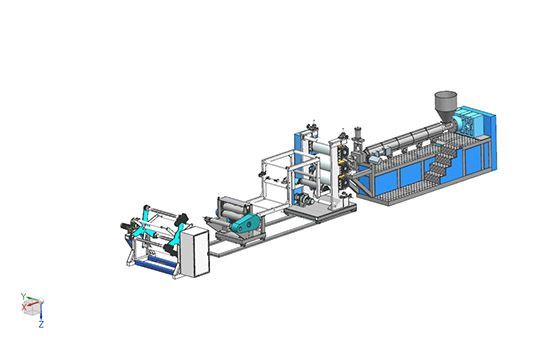

(2)Extrusion die

1、Structure: Hanger-style gradual flow channel, the die lip gap is adjusted by pull code, and the heating rod is built-in;

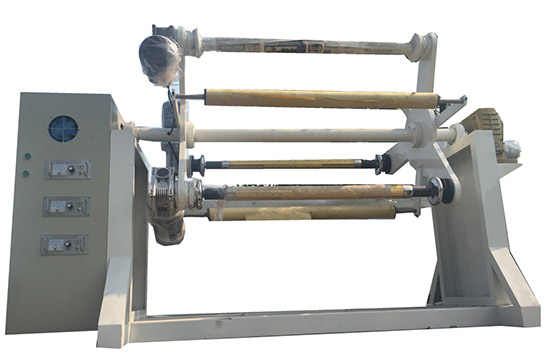

3、Three-roller calendering shaping part and structure: vertical three-roller independent transmission, frequency conversion speed regulation.

2. Roller gap adjustment method: gap oblique block screw adjustment.

4.Roller temperature control device

1. Three rollers are cooled by circulating water. 2. The inner spiral liner increases the cooling effect.

3. The surface of the roller is hard-plated and polished.

Three roll type | Independent step transmission |

Upper pressure roller | Ф350×900mm) |

Lower pressure roller | Ф350×850mm(Ziyang, Jiangsu) |

Cooling roll | Ф350×850mm(Ziyang, Jiangsu) |

Motor Power | 4kw |

Inverter control | INVT inverter |

Electric cabinet part

1. This machine adopts the domestic well-known brand INVT inverter with stable performance, reliable quality and excellent after-sales service.

2. We have used Shanghai Aoyi temperature control meter and pressure regulating module for a long time, which are reliable in quality and durable.

Electric cabinet part |

Main motor inverter | 55 kilowatts (Wannan Motor |

Motor inverter for calendering part | 4 kilowatts (Wannan Motor) |

Winding part motor inverter | 3 kW Wannan Motor |

Contactor | Schneider |

Low-voltage electrical appliances | Schneider |

Ammeter | Shanghai-Aoyi |

Voltmeter | Shanghai-Yatai |

air switch | Schneider |

Total power | 150kw |

Working power | 60kw |

Voltage | 380V 3 phase 4 wire |