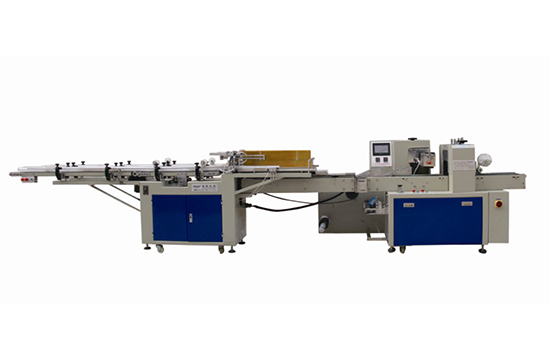

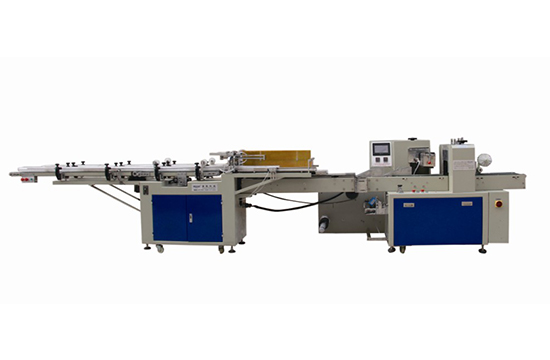

◆Structural characteristics

1. The machine adopts touch screen control, the main control circuit adopts PLC control, accurate measurement, automatic detection of electrical failure, simple operation and convenient adjustment.

2. Adopting high-quality dual-frequency conversion simple mechanical structure, easy maintenance, less wear and long life.

3. High-precision photoelectric detection and tracking, two-way automatic compensation, accurate and reliable.

4. The bag length does not need to be manually set, and the equipment is automatically detected and automatically set during operation.

5. The packaging speed and bag length are controlled by dual frequency converters, stepless variable speed, wide arbitrary adjustment range, and can be perfectly matched with the previous process of the production line.

6. Adjustable end sealing structure makes the sealing more perfect and eliminates the phenomenon of bag cutting.

7. The conveying table is stainless steel, and the host part is sprayed with plastic and baking paint. It can also be made into stainless steel according to customer needs. (All stainless steel requires an additional charge)

◆Features

1. Double-row automatic counting, automatic feeding, automatic packaging (2-200 pcs/pack);

2. The number of points can choose single point and double point, and the number of packaging products can choose single row and double row;

3. The minimum distance between cup and cup is 2mm;

◆Equipment can be added

1. Coding machine

2. Hanging hole knife

3. Long machine (exhaust)

4. Other equipment

◆Scope of application

Suitable for disposable plastic (paper) cups, such as milk tea cups, aviation cups, soy milk cups, coffee cups, etc.